Chinese mainland and Hong Kong scientists have jointly developed novel, lab-grown bone material that mirrors the elasticity, toughness, and strength of human bone, and said at a news conference on Monday that they believe it could soon transform major bone repair surgery and promise a faster and more complete recovery.

The material, dubbed “nano bone cement”, has been co-developed by researchers from the University of Hong Kong Li Ka Shing Faculty of Medicine (HKUMed), the University of Hong Kong-Shenzhen Hospital, and Zhejiang University.

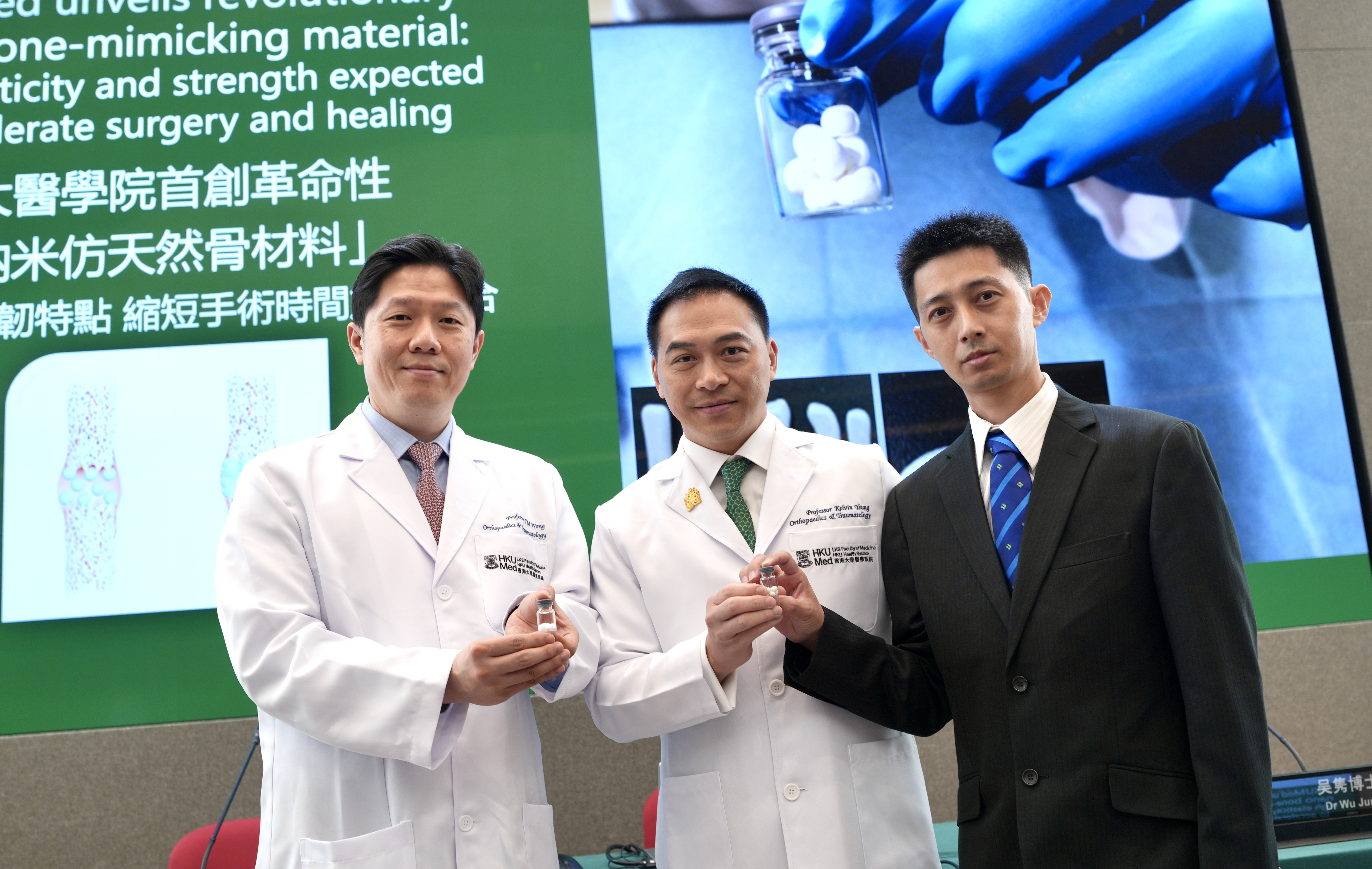

In lab tests, the material demonstrated “exceptional” elasticity, toughness, and strength, performing many times better than traditional bone graft materials and achieving over a 90-percent likeness to natural bone, said the research team’s leader, HKUMed’s orthopedic bioengineering professor Kelvin Yeung Wai-kwok, at the conference.

“This presents a promising alternative to traditional material used in orthopedic surgeries — procedures that carry significant risks due to their reliance on harvesting bone from the patient or a donor,” Yeung said. Using a patient’s own bone causes a second injury site, while bone from donors is scarce and carries the risk of rejection, he said, adding that traditional synthetic materials are brittle and weak.

The significance of this innovation is underscored by the growing number of bone defects worldwide — a trend that may pose global challenges, Yeung noted.

In 2019 alone, there were 178 million new cases of bone defects worldwide, resulting in a staggering total of 25.8 million years lived by people suffering with a disability, according to the World Health Organization.

A video shown at the conference demonstrated the new material’s superior qualities: A sphere of the new nano-bone cement bounced back into shape like rubber under pressure, while a sample made of traditional calcium phosphate material remained rigid and stonelike.

At the same event, Wong Tak-man, clinical professor at HKUMed’s department of orthopedics and traumatology, said that this material innovation will bring multiple benefits to orthopedic treatment.

“The new technology significantly simplifies surgical procedures and reduces overall operation time,” Wong said. He added that he expects the material — apart from filling defects in complex orthopedic surgeries, providing stability and promoting bone healing — to soon be expanded into neurosurgery and dentistry.

The project, launched in 2016, was funded by grants from the central authorities and the Shenzhen government, as well as the Health and Medical Research Fund under the Hong Kong Special Administrative Region’s Health Bureau.

“The project epitomizes the cross-border talent, investment (and) collaboration between Hong Kong and Shenzhen”, said Yeung, adding that he sees the mainland — the Guangdong-Hong Kong-Macao Greater Bay Area in particular — as the prime market for the technology’s potential commercialization.

“Benefiting from its favorable policies for translating technological innovations and easier access to funding, the Greater Bay Area will hold the greatest commercialization opportunities for the new material,” he said.

Yeung said the material has already been patented on the Chinese mainland, and he is bullish about its future commercial success there, but noted that full clinical trials to ensure utmost safety will be a lengthy process.

The toxicology safety data for regulatory approval alone may take one to two years to compile, added Yeung.

Contact the writer at wanqing@chinadailyhk.com