Editor’s note: In the vibrant Guangdong-Hong Kong-Macao Greater Bay Area, future-oriented innovations are the driving force behind rapid development. This column will highlight how innovators are overcoming developmental limitations and pioneering technological and institutional breakthroughs to inject a fresh impetus into future growth.

Zhang Junrong, who is responsible for user experiments at the China Spallation Neutron Source, a world-leading scientific project in Dongguan, Guangdong province, recalls a company conducting tests for more than 20 days at the facility, which operates around the clock.

This is an “exceptionally long” duration for user experiments, Zhang says. Most users with scientific purposes typically conduct their experiments for just one or two days, with some visiting the facility for several days throughout the year.

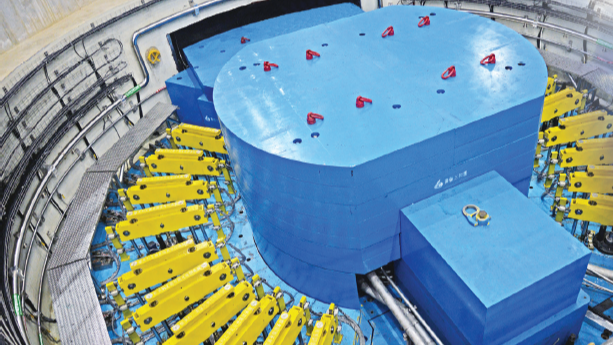

As the first spallation neutron source in China and the fourth worldwide, the CSNS serves as a supermicroscopy to explore the inner structure of materials in an efficient and nondestructive way. It is also a potential game-changing tool for strategic industries to break technological bottlenecks and fuel economic growth.

The facility experiences intense physical reactions that are invisible to the naked eye. Accelerated almost to the speed of light, protons are shot out like shells, striking heavy metal targets. The large number of neutrons that have been released there are the ideal “probe” for humanity to observe the microscopic world.

An increasing number of enterprises are using the facility to examine and optimize their products. With short research and development cycles, they often repeatedly test their products over a condensed period, before swiftly bringing the next product for evaluation.

“It has never been the case that testing a product just once or twice leads to success.

Such situations either indicate a lack of understanding of our device or that our device can’t serve their demands,” says Zhang, deputy director of the Neutron Science Division of Dongguan campus research branch under the Institute of High Energy Physics, Chinese Academy of Sciences.

Compared to scientific research, serving company users requires quick responses and long-term support. After every experiment, researchers at the CSNS need to analyze the results and explain to the concerned enterprise how they can help improve their products.

Deeper collaboration

These changes within the CSNS reflect a broader trend of accelerating the industrialization of the nation’s major scientific and technological infrastructure, commonly known as “large scientific facilities”. This shift is expected to support enterprises to achieve a quantum leap in research capabilities to explore the previously inconceivable, calculate the previously incomputable, and create what was once deemed impossible.

As the first national-level scientific infrastructure operating within the Guangdong-Hong Kong-Macao Greater Bay Area, the CSNS has achieved many outcomes in this area since its launch seven years ago.

It has facilitated improvements in lithium battery performance and shale extraction efficiency; safety checks for airplane engines, as well as for high-speed train wheels.

Making use of the facility, scholars from Hong Kong universities have advanced researches into amorphous alloy materials that can significantly enhance the lifespan of foldable smartphone hinges, as well as creating “super steel”, which has set world records for strength, ductility, and toughness.

Technologies developed by the CSNS also led to the birth of its first industrialization project — a boron neutron capture therapy (BNCT) device, an innovation used for radiation treatment that can accurately kill cancer cells, without harming surrounding tissues.

This device began clinical trials at Dongguan People’s Hospital in May. If successful, it could be officially implemented by the end of next year.

The second phase of the CSNS is expected to be completed by 2029, which will bring the number of its neutron instruments to 20 and significantly enhance the facility’s capabilities to boost industries.

When collaborating with enterprises, Zhang has also noticed a progressively smoother communication process.

“In the initial stages following the CSNS’ establishment in 2018, companies often struggled to understand how these theories about the composition of matter could benefit them. It was hard to reach a dialogue and we often needed university professors to act as translators,” Zhang says.

The situation has since improved significantly, with many leading companies and startup teams led by university scholars forming a clear understanding of how to harness the facility’s considerable power.

As communication deepens, ideas sometimes clash, but Zhang views this as a natural process that aids in refining products.

Under the current intense industry competition and foreign blockades on core technologies, the significance of such major scientific infrastructure will be further emphasized, he believes.

Alongside the CSNS, government authorities in the country’s various technological hubs have also begun to attach greater importance to boosting the integration of scientific facilities with industry.

Starting Aug 1, Shanghai began offering a 50 percent subsidy for companies on the cost of using major scientific facilities, capped at 1 million yuan ($139,000) per company annually.

Enterprises making significant investments in basic research can also receive a one-time subsidy of between 2 million and 10 million yuan.

Last year, Guangdong vowed support for enterprises to leverage large scientific facilities. The province will also expedite the construction of pilot platforms to enhance technology transfer.

Incubators for innovation

In the eyes of experts, there are promising prospects for large scientific facilities to empower enterprises with disruptive frontier technologies at all levels, enabling them to reduce research and development costs and risks, achieve independence in core technologies, and uncover new growth opportunities.

They can also expedite the cultivation of innovative industry chains and clusters, fuel regional growth, and bring exponential economic returns. These facilities serve not only as a telescope for scientific exploration, but also as an incubator for industrial revolution.

Other facilities in the Greater Bay Area are entrusted with a similar mission. Early in the planning stages for its major scientific facilities studying synthetic biology and brain science, Shenzhen began to build a cluster of “future industries”. The two scientific instruments, nestled in Guangming

Science City, an emerging innovation hub in the Greater Bay Area, have demonstrated their industry-nurturing potential despite only having started up in December 2024.

Gathering intelligent, automated, and high-throughput equipment, the Shenzhen Synthetic Biology Infrastructure has created a “biofoundry” that undertakes processes like DNA assembly, gene editing, and cell culture.

It has helped raw material companies to become suppliers to global giants in the pharmaceutical and cosmetic fields. Innovative companies account for 30 percent of its total users, and more than 120 synthetic biology startups have gathered in the vicinity, with a total valuation of approximately 40 billion yuan.

Featuring more futuristic studies, the Shenzhen Brain Science Infrastructure aims to be a global oriented, cross-species platform for all types of innovative brain science.

Integrating animal breeding, phenotypic analysis, and genetic analysis, the facility has extensive application potential.

It has propelled studies on treating neurodegenerative diseases (like Alzheimer’s) and into brain cognition, while accelerating the screening and certification of new drugs. It also aims to achieve breakthroughs in braincomputer interface technology.

In the era of artificial intelligence, computing power has become a strategic asset, and the National Supercomputer Center in Guangzhou is seizing the opportunity to expand its application horizons.

Among the world’s five most influential supercomputing centers, the Guangzhou institution has opened a new application domain in light of the AI industry’s rapid growth, to support the development of large AI models.

The facility’s powerful computer simulation has helped fuel the upgrading of traditional industries. It has been used to improve the development of new cars and ships; test the structure of high-performance manufacturing materials and new biomedical drugs; and explore the most efficient ways to utilize wind and solar power.

An associate professor at Sun Yat-sen University, which manages the center, Huang Dan, who is conducting research on highperformance computing, connects the surging demand for computing power to the transformation of enterprises.

Such changes include the shift from component assembly to comprehensive self-design and development, enhanced involvement in mid- to high-end manufacturing, and the trend toward intelligent systems.

Huang foresees that multimodal large models, autonomous driving, embodied intelligence, manufacturing upgrades, and nuclear energy utilization will generate substantial computing demand, which the center will focus on developing.

To better align with local industries, the institution is continuously expanding its branches. Its subcenters now cover most cities in the Greater Bay Area, leveraging the “super brain” to inject digital momentum into key local industries.

Sharing outcomes

To further translate the substantial investment in scientific facilities into new quality productive forces, experts have highlighted the significance of information sharing, collaborative mechanisms, and the industrialization of experimental results.

Zhang says that while the CSNS has invested significant resources in tackling the specific challenges of companies from across industries, competition and insufficient communication have impeded the sharing of technological outcomes.

He hopes that the government or industry associations can serve as a bridge, enabling solutions provided by the CSNS to benefit more enterprises and accelerate industrial development.

Instead of waiting to serve the enterprises’ demands, the institution will enhance its outreach to enterprises and adopt a more proactive approach to guide them through the use of this advanced scientific platform.

Looking forward to closer collaboration among scientific facilities, Huang says that many facilities require computing power for data analysis. Deeper cooperation could facilitate data transfer, providing enterprises with a one-stop service, he adds.

Prioritizing the enhancement of service capacity amid booming demands, Huang says that the center aims to secure stable and compatible domestic chips to address the international chip embargo, expand interdisciplinary talent, and further increase computing and storage capacity.

With a similar goal, the Shenzhen Synthetic Biology Infrastructure aims to leverage AI and national pilot platforms to support product design and testing. It will also engage in international standard-setting to boost the global competitiveness of domestic industries.

Liu Zhigang, head of the oncology department at Dongguan People’s Hospital, which is conducting the BNCT clinical trial, says advanced scientific facilities in the Greater Bay Area have different strengths in disease treatment. There is significant potential to create integrated treatment plans, promoting regional development of the healthcare industry.

In his view, to promote the applications of large scientific facilities’ outcomes, such as BNCT, the efficacy and versatility of therapies, cost and scale of devices, establishment of industrial chains, and support from health insurance are all crucial factors.

In Zhang’s words, serving the industry has always been a mission of major scientific and technological infrastructure. As enterprises have become the main drivers of the nation’s technological innovation, it is time for these facilities to get closer to them in order to turbocharge industrial upgrading.

Contact the writer at bingcun@chinadailyhk.com