Hong Kong technology startups have performed remarkable feats in the Hetao Shenzhen-Hong Kong Science and Technology Innovation Cooperation Zone, testifying to the zone’s resolve to create a world-class intermediate test and transformation cluster in the Guangdong-Hong Kong-Macao Greater Bay Area to bridge the gap between labs and markets. Zhou Mo reports from Shenzhen.

Editor’s note: Development of the Hetao Shenzhen-Hong Kong Science and Technology Innovation Cooperation Zone is speeding up, with Shenzhen Park and Hong Kong Park forming a unified entity that promotes cross-border innovation and technological development. This three-part series illuminates the transformative role of the zone in breaking down barriers and fostering collaboration between the two regions. The first article focuses on how Hetao facilitates commercialization of science and research findings.

In the heart of the Hetao Shenzhen-Hong Kong Science and Technology Innovation Cooperation Zone in Shenzhen, Vista InnoTech — a startup nurtured at Hong Kong Science Park — celebrated its technological breakthrough by delivering the world’s smallest mobile MGS (micro gimbal stabilizer) — capable of capturing sharp images in low light and shaky conditions — to South Korean tech giant Samsung Electronics.

For Vista InnoTech, the achievement isn’t just a victory for its technology. It attests to its prowess in scientific achievement transformation that has been turbocharged at Hetao — a 3.89-square-kilometer zone comprising a 0.87-square-kilometer park in Hong Kong to the south of Shenzhen River and a 3.02-square-kilometer park in the Chinese mainland’s tech powerhouse to the north.

Before setting up shop at Hetao, the tech firm had to face the challenge of turning their laboratory ideas into prototypes and products. “When Hong Kong Science Park decided to establish its Shenzhen branch at Hetao, we signed up immediately,” recalls Ada Sun, chief operating officer of Vista Innotech.

READ MORE: 15 State Key Labs hold great promise for HK

The move wasn’t just about location. It was about finding a space where gaps between research and development, transformation and industry could be plugged.

“We leverage Hong Kong in breaking through technological ceilings and take advantage of Shenzhen to overcome cost and efficiency hurdles. Through Hetao’s bridging platform, we’ve been able to build seamless links among innovation, industrial and market chains,” says Sun.

Vista Innotech’s accomplishment reflects Hetao’s efforts to bridge gaps across research and development, scientific achievements transformation and industrialization to form an innovation closed-loop.

Bridging the valley

The leap from R&D to viable products is often seen as the “valley of death” for startups. According to a study published in Financial Market Research in April 2023, the conversion rate of scientific and technological achievements in China stood at about 30 percent — lower than the 60-70 percent in developed countries.

The country’s relatively low conversion rate has, to a certain extent, undermined the market value and commercial returns of such achievements, and created a bottleneck that hinders innovation-driven development, the study said.

Qiu Hesong, founder and president of Hong Kong-based medical tech firm Jiying Technology, which specializes in artificial intelligence-powered genetic tech development and applications, has deep feelings about the hardships in translating research into practical applications. His company’s work on the Helicobacter pylori and early gastrointestinal cancer screening system had to overcome virtually insurmountable obstacles, given the limited availability of real-world testing data in Hong Kong.

“Due to the need for a substantial amount of specialized data, we could only establish the methodology in Hong Kong. The scarcity of real-world testing data in the city made it difficult to quickly implement effective testing,” he says.

The hitch, however, was fixed at the Hetao cooperation zone, where Jiying Technology has forged partnerships with more than 40 Chinese mainland hospitals, allowing it access to real-world data.

“The model of conducting R&D in Hong Kong and real-world testing and fast industrialization on the mainland has significantly hastened the transition from research to market, providing valuable time and saving substantial costs in product commercialization,” says Qiu.

In transforming scientific research into products, one critical step is the intermediate test that refers to small-scale trials of new products before proceeding to mass production. The process allows researchers and tech firms to test their products, identify and solve potential technical issues, thereby reducing investment risks and shortening product time to market.

According to a survey by the China High-tech Industrialization Association, the success rate of commercializing scientific and technological achievements with intermediate tests could reach 80 percent, compared to 30 percent for those without such verification.

The Development Plan for the Shenzhen Park of Hetao Shenzhen-Hong Kong Science and Technology Innovation Cooperation Zone issued by the State Council — China’s cabinet — in August 2023, calls for the park to harness an “intermediate test and transformation cluster” in the Greater Bay Area.

The task of realizing transformation from research and development to engineering should be accelerated, and world-class intermediate test and transformation service platforms should be created, according to the blueprint.

Since the plan’s promulgation, 10 industry-level intermediate test platforms have been licensed, covering areas like new-generation information technology, biomedicine, artificial intelligence and the digital economy.

Break the limit

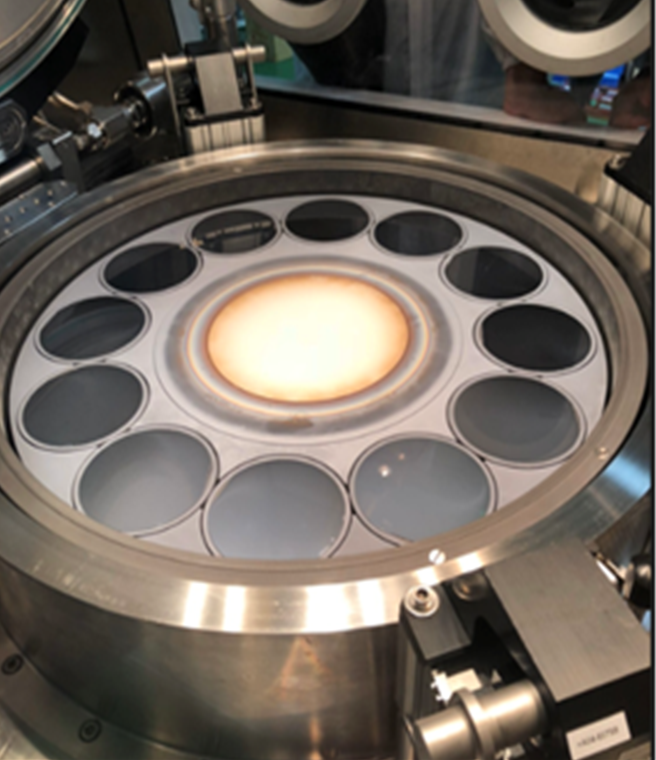

Shenzhen ComingLight Optic-electric Co Ltd runs one of the intermediate test platforms that have gone into operation at Hetao. The platform focuses on dealing with tapeout process of optical chips for research institutes and businesses.

Tapeout is a process between chip design and mass production. It involves producing a small batch of samples to test whether the designed chips function well and how the design can be optimized, and is a critical step in the manufacturing process for chips.

According to Zhang Liyong, general manager of Shenzhen ComingLight Optic-electric, tapeout in China lags behind that of the United States and Europe, with Chinese research institutes and chip firms having to rely heavily on overseas platforms for the testing, hindered by a long processing period and high costs.

“We hope to be able to deal with these challenges and bridge the gap between lab achievements and large-scale production, so that industry players in the technological field can speed up their R&D work without being constrained by bottlenecks,” says Zhang.

While tapeout in the US or Europe could last three months, the process on the Hetao platform takes only half the time, he says, and the cost is only one-third or even a quarter of that on overseas platforms.

The intermediate test platform has so far teamed up with over 10 universities, research institutes and enterprises across the country, including The Chinese University of Hong Kong, Shenzhen, the Beijing Institute of Technology and Peng Cheng Laboratory.

The sophistication of Hetao’s industry-academia-research collaborative ecosystem is pivotal behind the establishment of the Hong Kong Polytechnic University Shenzhen Technology and Innovation Research Institute in the zone.

Shi Wenzhong, director of the institute, and his research team are focusing on geo-artificial intelligence and reliable spatial data analytics — a high-tech field that can be applied in multiple areas, including transportation, urban environment and road maintenance. About 20 high-caliber professionals from PolyU, including professors, associate professors and internationally renowned experts, have been conducting research at the research institute in Hetao, along with over 10 postgraduates from the university.

ALSO READ: Hetao boosts Hong Kong-Shenzhen ties

“We hope to leverage Hetao’s platform to connect with Shenzhen’s urban construction, transportation, environment and other departments, and build partnerships to obtain real-scenario data for training AI models and apply technologies to solve practical problems,” says Shi.

While hailing Hetao’s core advantages — its proximity to Hong Kong and strong resource matching capability — he admits that challenges remain in Shenzhen-Hong Kong collaboration in the zone.

“One major challenge lies in the inconsistency of standards,” Shi points out. “In planning land use in the Greater Bay Area, for example, the mainland’s land use standards cover over 100 categories, while Hong Kong has only 20 to 30. Such variations impede the promotion of unified regional planning.”

Shi suggests that standard unification should be stepped up across key fields to unlock the full potential of the zone’s innovation ecosystem and deepen cross-boundary collaboration.

Qiu hopes Hetao could introduce more preferential policies for enterprises and talents, and help high-tech companies to use data in areas like life health and biomedicine.

Contact the writer at sally@chinadailyhk.com