Humanoid robots are making their presence felt across the corporate world, helping to raise national productivity and reshape industries. As Chai Hua reports, China is at the forefront in the revolutionary tech race, with more than a third of the companies in the sector being Chinese.

Editor’s note: As artificial intelligence becomes increasingly vital in international competition, embodied AI could be the next big thing. In a series of articles, entitled Hands-on AI, China Daily looks into the technology’s applications in different scenarios, with the first focusing on humanoids in factories.

At an automobile plant in Shenzhen, a humanoid robot picks up a box of assembled electronic components and places it onto a self-drive trolley. Another robot meticulously inspects the quality of an electric automobile’s headlights as its “colleague” inside another vehicle tests the air-conditioning controls using voice commands.

It’s no longer a scene from a science fiction blockbuster. It’s the reality at electric vehicle factories across the Chinese mainland, with humanoids being trained to do multiple tasks in different industrial scenarios.

READ MORE: Shenzhen thinking long term

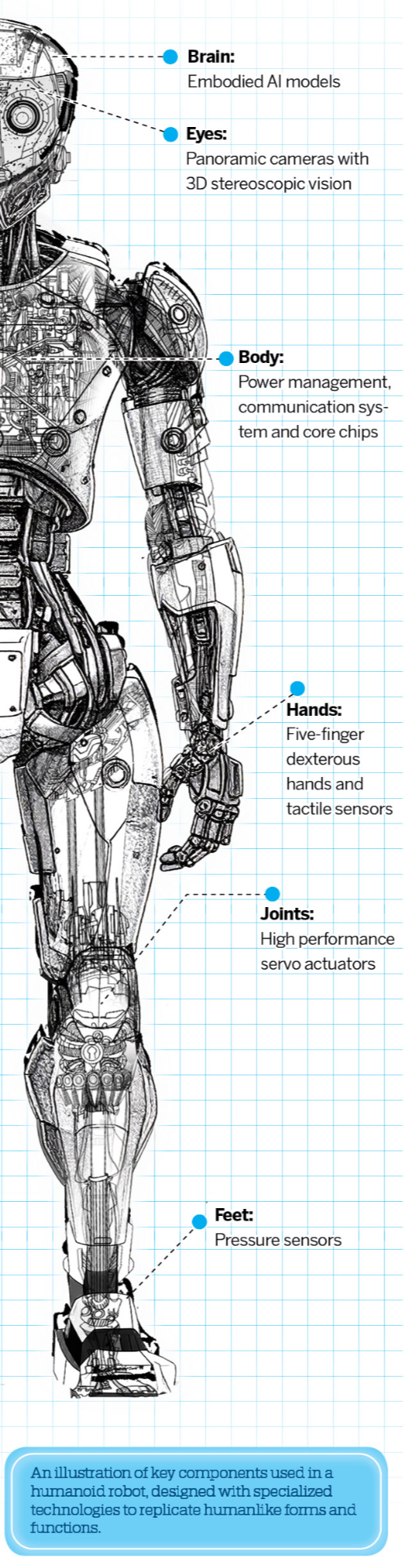

The robots have “eyes” — panoramic cameras with 3D stereoscopic vision — and hands with five-fingered dexterity and tactile sensors. They also feature actuators-linked and mini motor-empowered “muscles” and “joints”, all of which help them to accomplish labor-intensive jobs.

More importantly, these sci-fi-turned-reality machines are digitally “ensouled” by embodied artificial intelligence technology.

Embodied AI, where the technology is integrated into physical systems, enables intelligent agents to interact with the environment in a physical form. Unlike large language models, embodied AI focuses on understanding and responding to physical environments. Direct interaction with its surroundings marks a significant shift from AI paradigms. This technique has fueled breakthroughs in key applications, with humanoid robots standing out as a prime example.

“Artificial intelligence is becoming a cornerstone of international competition. Embodied AI — where intelligent software meets smart hardware — could be the next big thing. Humanoid robots, regarded as the ultimate platform for embodied intelligence, have the potential to drastically enhance national productivity and reshape industries,” says Michael Tam, chief brand officer of Hong Kong-listed UBTech Robotics.

Humanoid ‘workers’

According to a recent report by Morgan Stanley, the global humanoid-robots market could be worth $5 trillion by 2050. The number of robots that resemble and act like humans is likely to reach nearly 1 billion by 2050, with China currently leading in development, the report said.

Automobile manufacturers are particularly eager to create their own humanoid robotics. Elon Musk, CEO of US electric vehicles giant Tesla, said in January he aims to deploy 10,000 Tesla Optimus humanoids at the company’s factories this year.

Guangzhou Automobile Group unveiled its third-generation humanoid robot, GoMate, in April and aims for small-scale production next year. Electric vehicle maker Xpeng Motors’ robot, Iron, made its debut in November.

The robotic revolution comes as the manufacturing industry grapples with a severe labor shortage although considerable strides in automation have been made in recent years.

“On assembly lines, processes involving consistent replication of each step can be automated. However, certain tasks still require human labor,” says Chen Qifeng, associate professor at the Department of Computer Science and Engineering and the Department of Electronic and Computer Engineering of The Hong Kong University of Science and Technology.

At workshops in automobile factories, the final assembly line remains the ultimate challenge in achieving fully automated production. Many young workers today are increasingly reluctant to take on labor-intensive and monotonous jobs, especially in poor working conditions, like testing the electric vehicle charging equipment again and again, and moving boxes in warehouses without air-conditioners.

Robot makers are intensifying efforts to address the labor gap. “Our robots are already training at factories of electronics giant Foxconn, major Chinese delivery service provider SF Express, Chinese EV-maker BYD, and Audi’s EV factory in China,” notes Tam.

UBtech’s robot “Walker S1” is 172 centimeters tall and weighs about 76 kilograms. The four-limbed robot can walk like a human and carry up to 15 kg. For larger or heavier cargo, two of these robots can work together to handle the load. Besides labor-intensive jobs, they can also perform hazardous tasks that could be harmful to humans, like conducting leak tests on air-conditioning coolants.

“It isn’t just about investing in cutting-edge technology, but about transforming the entire manufacturing model, supply chains and, most crucially, the future competition landscape,” says Tam. “This transformation determines whether today’s manufacturing heavyweights can take the lead in production efficiency in the years to come.”

Challenges ahead

However, industry insiders suggest that the sector is still in its development, with various obstacles, including limited perception capabilities and low efficiency. So industry experts and insiders believe it remains a distant goal to fully replace human workers with such robots.

“At present, their capabilities are comparable to the level of autonomous driving technology from a decade ago, perhaps, sufficient for highways, but not for navigating complex environments,” says Chen.

He points out that the learning efficiency of humanoid robots is still low. “Most models require extensive training data — often hundreds or thousands of similar data points — to teach a robot a particular skill.”

“A crucial technology for humanoid robots in the future is the ability to learn a new skill from minimal instructions, such as a few words, video demonstrations, or examples,” he says.

Chen says he believes humanoid robots are poised to become increasingly intelligent, particularly suitable for scenarios involving nonfixed workflows, with a strong emphasis on their cognitive capabilities.

“Even simple tasks like carrying and stacking boxes of components and materials, which are easy for humans, are highly complex for robots,” said Tam.

He explained, robots must consider variables such as box sizes, stacking patterns and the height difference that require advanced adaptability.

“There won’t be anyone actively ‘controlling’ these robots. Robots will need to ‘think’ and react on their own,” says Tam. Besides, it also requires integration with factory databases, coordination with automated guided vehicles and real-time updates to production schedules.

Efficiency is another challenge, he says. In the early stages, robots required four to five times longer than human workers to move the same amount of boxes.

However, after nearly a year of training, equivalent to 700 hours of work, robots have achieved 50 to 60 percent of human efficiency. “The goal is to reach 80 percent of human efficiency, which we see as a milestone that will enable mass production of such robots,” says Tam.

He says he believes such a degree of efficiency would be sufficient to make robots economically viable for industrial applications since machines can run 24 hours a day, but fully replacing human workers remains “a distant goal”.

In the manufacturing scenario, the global average robot density reached a record 162 units per 10,000 employees in 2023 — more than double the 74-unit average measured in 2017, according to a report by the International Federation of Robotics released in November.

When breaking these numbers down by country, China’s robot density reached 470 units per 10,000 employees in the same year, ranking third globally just behind South Korea and Singapore.

ALSO READ: China's Shenzhen tech hub to expand scale of AI terminal industry

According to Shi Xiaoxin, product director at Xpeng Robotics Center, their humanoid robot’s efficiency is about 20 percent that of a human’s. “We are still working on how a robot can stably control the body to perform as we would expect. And, eventually, robots can learn to work independently,” he says, adding it’s like putting a “soul” into a machine.

One advantage of car companies in building robots is that they have abundant experience and expertise in hardware products. “We have our own chips. For the hardware, we aren’t worried at all,” he says.

Xpeng Robotics Center is collecting data and training robots on its production line in Guangzhou. According to Shi, two types of data are actually meaningful — how human workers perform tasks and how a robot can complete them in the same scenario. He expects to see robots actually working in Xpeng companies within two years. “Maybe, thousands of them, but, we are not replacing workers.”

Shi predicts that, in about two to three years, they can assign part of the workload to robots, but not completely.

The Future Forward

• Learn new skills from minimal instructions

• Reach 80 percent of human efficiency

• Achieve mass production

Contact the writer at grace@chinadailyhk.com