The bets are high on Hong Kong lifting the recycling business and encouraging the public to drive the circular economy. As Stacy Shi reports, ambitious projects at the city’s green model, EcoPark, testify to its resolve to propel the new energy industry.

Amid the sprawling grounds of EcoPark — Hong Kong’s showpiece for a greener future tucked in a remote far western corner of Tuen Mun district in the New Territories — a new industrial vision is taking shape.

Workers tirelessly install electrical and mechanical equipment at the 9,420-square-meter facility, placing an ambitious bet, not on the special administrative region’s hallmark finance or trade label, but green technology.

The plant, developed by Chun Yang International, a subsidiary of Envision Greenwise Holdings, is the SAR’s first large-scale electric vehicle lithium battery recycling facility — a key initiative to stimulate the recycling business.

READ MORE: Cities on green wheels

Scheduled to begin operations in the first half of this year, the project is a cornerstone of a broader strategy outlined in Chief Executive John Lee Ka-chiu’s 2025 Policy Address to position the SAR as a critical player in advancing the new energy industry.

Cleaner skies

Lee outlined three concrete measures to take the emerging sector forward. Besides hydrogen-energy projects already underway, two other industrial chains are relatively new to Hong Kong — one is focused on the aviation sector, tackling one of the most stubborn challenges in the transport field concerning the SAR government’s target for flights departing from Hong Kong International Airport to use 1 to 2 percent sustainable aviation fuel by 2030.

While such a goal seems modest compared to the European Union’s mandate of 6 percent by the same year, it’s a strategic starting point. The Environment and Ecology Bureau says sustainable aviation fuel, derived from feedstock like used cooking oil, can reduce lifecycle carbon emissions by more than 80 percent, compared to conventional jet fuel.

The real strategy, however, lies in building the entire supply chain. “The Environment and Ecology Bureau has been working with the Chinese mainland to enable a local enterprise that’s a major global sustainable aviation fuel supplier to develop its business in the Guangdong-Hong Kong-Macao Greater Bay Area,” the SAR authorities say.

The initiative will cover the upstream collection of raw materials and establishing production and large-scale manufacturing plants. The Transport and Logistics Bureau is also considering a sustainable aviation fuel blending facility to provide cheaper blended jet fuel in the long term, thereby boosting the competitiveness of the local aviation fuel industry and bolstering the bargaining power of airlines.

Green from ground

In line with the city’s sky-high ambitions, Hong Kong is also boosting its capacity to handle ground-level waste of the electric revolution — used EV batteries. Electric vehicles now make up 70 percent of new private car registrations in Hong Kong, accounting for about 12 percent of all vehicles on the city’s road.

As EV batteries, which typically last eight to 10 years, gradually lose their power, the need for a local, sustainable recycling solution is becoming increasingly urgent.

“Previously, there wasn’t any industry in Hong Kong that processed lithium batteries,” says Shirley Kwok Ho-yee, Chun Yang’s managing director. “They were all exported to Japan or South Korea for processing.”

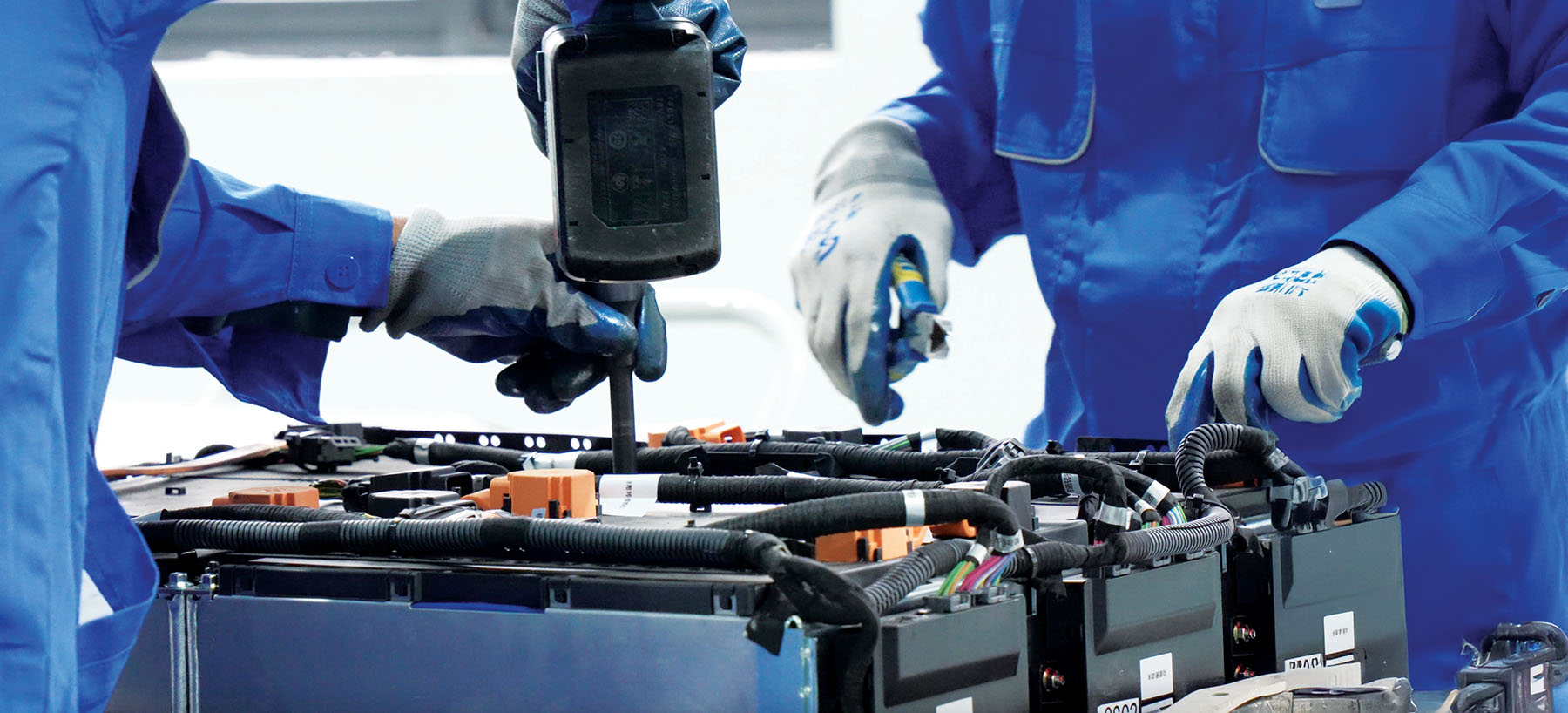

The company’s new facility, equipped with German technology and an automated identification system designed locally to handle the diverse range of battery types and brands found in Hong Kong, will change that. The process involves safely disassembling batteries, then either preparing them for “second life” use in less-demanding applications like portable solar storage, or shredding them into a valuable substance known as “black mass”.

The black mass, rich in critical minerals like lithium, cobalt and nickel, is central to the operation’s economic and strategic logic. “These are strategic resources,” Kwok says. “By supplying them to battery manufacturers, we can directly support the production of one type of mainstream EV batteries — new lithium batteries.” She estimates that the facility can produce over 5,000 metric tons of black mass annually in its initial phase.

Riding the wave

Such an approach reveals a coherent vision. Hong Kong aims to leverage its unique status as a global city within the country to promote strategic energy flows.

Established industry players on the mainland are equally optimistic. Xu Youbin, board secretary at Jinsheng New Energy, a major mainland battery recycler, sees clear potential for collaboration.

Jinsheng, based in Zhaoqing, Guangdong province, and founded in 2010, was initially engaged in nonferrous-metal smelting and rolling processing. Its lithium battery recycling business line was set up in 2014, recognizing the development prospects of the new energy vehicle and battery recycling sector, as well as the strategic necessity to reduce dependence on foreign supplies of critical mineral resources.

With more than a decade having elapsed since the company’s launch, Xu has split the period into two stages — a long and arduous phase of accumulation from 2014 to 2020, when EV development progressed relatively slowly due to technological and cost constraints; and a subsequent phase of explosive growth after 2021, as both technology and costs finally gained market acceptance, leading to a surge in new energy vehicle sales and energy storage installations.

But the path hasn’t been smooth sailing. Just four years into this explosive growth, Xu says he believes the industry has completed a full market cycle.

He points to the roller-coaster prices of lithium carbonate — a vital product in battery recycling. “Before the industry took off around 2021, the price was about 40,000 yuan ($5,750) per ton. By November 2022, it had skyrocketed to over 600,000 yuan per ton,” he says. “Then, starting from December 2022, the price began to fall rapidly, hitting a low of just over 50,000 yuan per ton in the first half of 2025, followed by a modest recovery since, and (as of October) around 75,000 yuan a ton,” he adds.

“This trajectory from 2021 to mid-2025 represents a complete cycle — from trough to peak, then back to a trough, and now potentially at the start of a new upward phase,” Xu says.

Despite the turbulence, he sees clear signals of a resilient recovery. The confidence is backed by market projections. According to the State Administration for Market Regulation, China’s domestic power battery recycling volume had surpassed 300,000 tons in 2024, representing a market scale of 48 billion yuan, and is forecast to exceed 100 billion yuan by 2030.

“Downstream demand from EVs and energy storage has also continued to grow rapidly. China’s EV sales still grew over 30 percent year-on-year in the first half of 2025 on an already high base.”

Xu says he believes that as long as demand persists, the industry’s future is highly certain, a sentiment he says is widely shared across the sector.

Strategic links

As the grand opening of Hong Kong’s EV battery recycling milestone approaches, a key partnership ensures that the facility can meet its high-tech ambitions. The Hong Kong Productivity Council has been appointed as technical consultant for Chun Yang’s project, supported by the HKSAR government’s New Industrialization Funding Scheme, providing comprehensive assessments and advice for the new smart production line.

The tailor-designed smart battery material production line project, estimated to get HK$15 million ($1.92 million) from the funding program, is expected to inject momentum into Hong Kong’s green economy.

Attending a technical consultant agreement signing ceremony held by both sides on Jan 16, Secretary for the Environment and Ecology Tse Chin-wan said the battery processing plant “not only addresses the disposal of retired electric vehicle batteries locally, but also converts them into recycled black mass to supply the Chinese mainland and neighboring regions”.

Xu sees the new Hong Kong player as a potential partner with strong operational capabilities.

“The market is vast. No single company can monopolize it,” he says, emphasizing the natural synergy in the supply chain. He envisions a model in which the Hong Kong facility handles upstream collection and preprocessing, feeding black mass to mainland technical experts like Jinsheng for complex refining.

The division of labor leverages the comparative advantages of both sides, creating a complementary partnership that could maximize value across the entire industry chain, Xu says.

Envision Greenwise, to which Chun Yang belongs, has teamed up with mainland battery giants like Guangdong Brunp Recycling Technology Co, a subsidiary of EV battery giant Contemporary Amperex Technology, and Gotion High-Tech Co to explore pathways for the reuse and repurposing of recovered materials.

ALSO READ: CUHK develops safer lithium battery for electric vehicles

“By processing the batteries here, we can supply these materials, including black mass and other metals, such as copper and aluminum, back to the Greater Bay Area to produce new batteries in order to contribute to the nation,” Kwok says.

Beyond viewing it as a production site, she says she hopes the plant will be a future hub for research and talent. “Experts have knowledge — the real challenge is application,” she says.

By providing the space, materials and real-world feedstock for experimentation, the facility may attract researchers to Hong Kong and turn scientific concepts into operational improvements, such as raising material purity.

Kwok says Hong Kong might have been overlooked once in the new energy sector. “Now, with government support for talent and new industrialization, we want to change that by offering a place where research can take shape.”

The momentum is building up. From the blueprints for sustainable aviation fuel blending facilities to the emerging green structure at EcoPark, Hong Kong is actively participating in the global energy transition.

It’s a calculated bet — the city’s future lies not only in the flow of goods and capital, but in pioneering how the world powers its journey.

Contact the writer at stacyshi@chinadailyhk.com