Maintenance and repair of high-tech equipment revolutionized by research innovations

With the completion and opening of projects such as the China-Laos Railway and the Jakarta-Bandung High-Speed Railway in Indonesia, along with the breakthroughs in domestic large aircraft and the aeroengine systems, the export volume of Chinese high-speed trains and airplane parts has been gradually increasing in recent years.

As a result, the maintenance of high-end equipment through innovation has become a major focus for Chinese researchers.

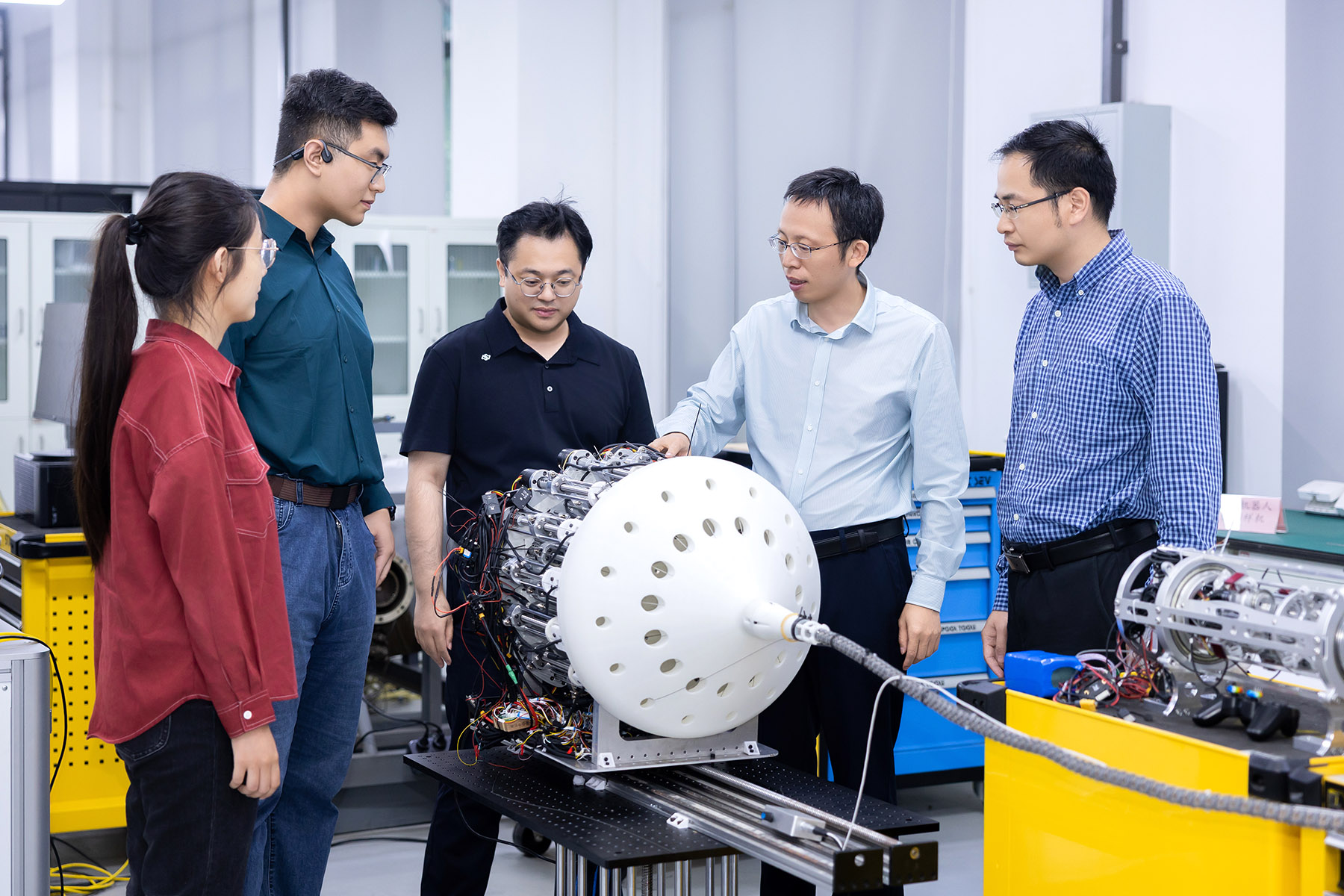

A team led by Chen Xuefeng, a professor at the iHarbour Academy of Frontier Equipment based at Xi'an Jiaotong University in Shaanxi province, has developed a biomimetic, snake-shaped robot that is forecast to revolutionize maintenance and repair work. The robot snake is capable of performing automated blade damage inspections without dismantling precision equipment like aeroengines, and can do other high-end equipment maintenance.

"In the past, inspecting an aeroengine required multiple technicians to work continuously in confined spaces for hours or to completely dismantle the engine, which was time-consuming and exhausting," said Chen.

READ MORE: China begins construction of new aeroengine test facility

"But in the future, our biomimetic robots will be able to perform minimally invasive maintenance without disassembling the engine. We can describe it as 'industrial minimally invasive surgery'," he said.

Last summer, Chen's team developed the insect-sized BATE (Boundary Actuation Tunable Energy-barrier) Jumper, a miniature robot with a strong jumping ability. This robot, only 15 millimeters in length, can jump 12.7 times its length vertically, and cover 20 times its length horizontally. Due to its compact and flexible design, the BATE Jumper has unique advantages in confined spaces and complex environments, making it extremely promising in fields such as exploration, search and rescue.

Complex applications

However, the team did not stop there. They targeted more complex application scenarios in the field of flexible continuum snake robots — particularly the inspection of aeroengines without the need to remove and dismantle them.

"The inside of an engine is like a metallic labyrinth," said Yang Laihao, an associate research fellow in the field of aeroengines at Xi'an Jiaotong University.

"In such complex and confined spaces, traditional rigid robotic arms struggle, whereas flexible continuum robots have great potential due to their superior dexterity and environmental adaptability," he said.

"However, current joint configuration designs face issues such as instability under compression, poor torsional performance, and insufficient load capacity. Additionally, under the influence of factors like gravity and friction, the end positioning error of these flexible continuum robots can increase exponentially with length, which remains a major obstacle to their practical application," he added.

To address these challenges, the team proposed several new joint designs from concepts such as contact-aided and active-passive hybrid configurations. They helped achieve a more than hundredfold improvement in bending stiffness, a twentyfold increase in torsional stiffness, and solved instability issues.

Yang said they have now achieved efficient and high-precision modeling of continuum robots, with efficiency reaching the millisecond level and repeat positioning accuracy now at the millimeter level.

The team has also developed multiple types of continuum robot systems for the maintenance of high-end equipment. They include fully active continuum robots with a length-to-diameter ratio exceeding 80, and active-passive continuum robots that can extend to several meters. These have been validated in various aviation equipment applications.

"I have seen aeroengine inspection technicians climb into long-narrow inlets to manually inspect blade cracks with flashlights. This often results in lumbar spine injuries, requiring job rotation every six months," Chen said, citing field surveys.

Redefining limits

The snake robots and miniature robots developed by the team are redefining humanity's exploration limits in confined spaces. They also show unique advantages in scenarios such as nuclear power facilities and aircraft fuel tanks.

"In the medical field, there are minimally invasive surgical robots," Chen said. "We have introduced this concept into the industrial field, developing robots for industrial minimally invasive 'surgery', promoting technology and model innovation in equipment maintenance. In the future, this will be applied in high-end equipment inspections in nuclear power and aerospace," he added.

As the team leader, Chen's educational philosophy mirrors his innovative research approach. He candidly tells every new doctoral student that choosing a scientific path is undoubtedly stepping into the gates of hell, and cannot have a work-life balance.

Behind this strict requirement is his profound understanding of the mission of scientific research.

"A university should undertake more pioneering tasks," Chen said. "Like how Samuel C.C. Ting (the world-renowned physicist) discovered the J particle (a new subatomic particle) — doing things that could be utilized in tens or hundreds of years — universities should lead the way."

"I ensure that each student's project will not be outdated in 10 years," he stated.

This philosophy has yielded fruitful results. The wind power monitoring and diagnostics system developed by the team now covers 60 percent of wind farms nationwide, and their blade-end timed detection technology has been hailed by international peers as a "sensational innovation."

In the field of managing aeroengine health, the monitoring and diagnostics systems developed by the team have been installed on various helicopters.

Innovation hub

The iHarbour Academy of Frontier Equipment at Innovation Harbor itself is a hub of innovation. Chen Xuefeng fondly recalls the construction process: "Without any funding support, university leaders quickly built 1.69 million square meters of buildings and over 5,000 housing units on 5,000 acres of farmland, thanks to the diligent efforts of the Western China Science and Technology Innovation Harbour."

This can-do spirit is vividly exemplified in the new era and deeply ingrained in Chen's work ethic.

Chen said one-third of the nation's aviation and half of its aerospace operations are in Xi'an. He believes that Shaanxi's deep roots in the aviation and aerospace fields offer his team unique advantages.

ALSO READ: Sci-tech sector maturing rapidly amid incentives

Based in China's western region, Chen's team has achieved global academic recognition. According to Elsevier's Scopus and SciVal database, over the past five years, the team has published more than 500 papers in mechanical fault diagnosis as the world's academic leader in the field, with total citations exceeding 20,000.

His research has been cited in patents by top companies such as General Electric and Aero-Engine Corporation of China, ranking first worldwide in influence in the field.

Today, Innovation Harbor has established joint research institutes with 230 leading enterprises, forming 88 deep-integration innovation consortiums.

Liu Tingyu contributed to this story.

Contact the writer at yandongjie@chinadaily.com.cn