Many people do not realize that there cannot be a world without production. Everything that nature does not provide has to be produced. In this respect, production technology is of vital importance for every country.

A country that has good production technology can produce high-quality products, and provide its citizens with high-quality goods, thus meeting their needs, and wants, and making them proud of the country.

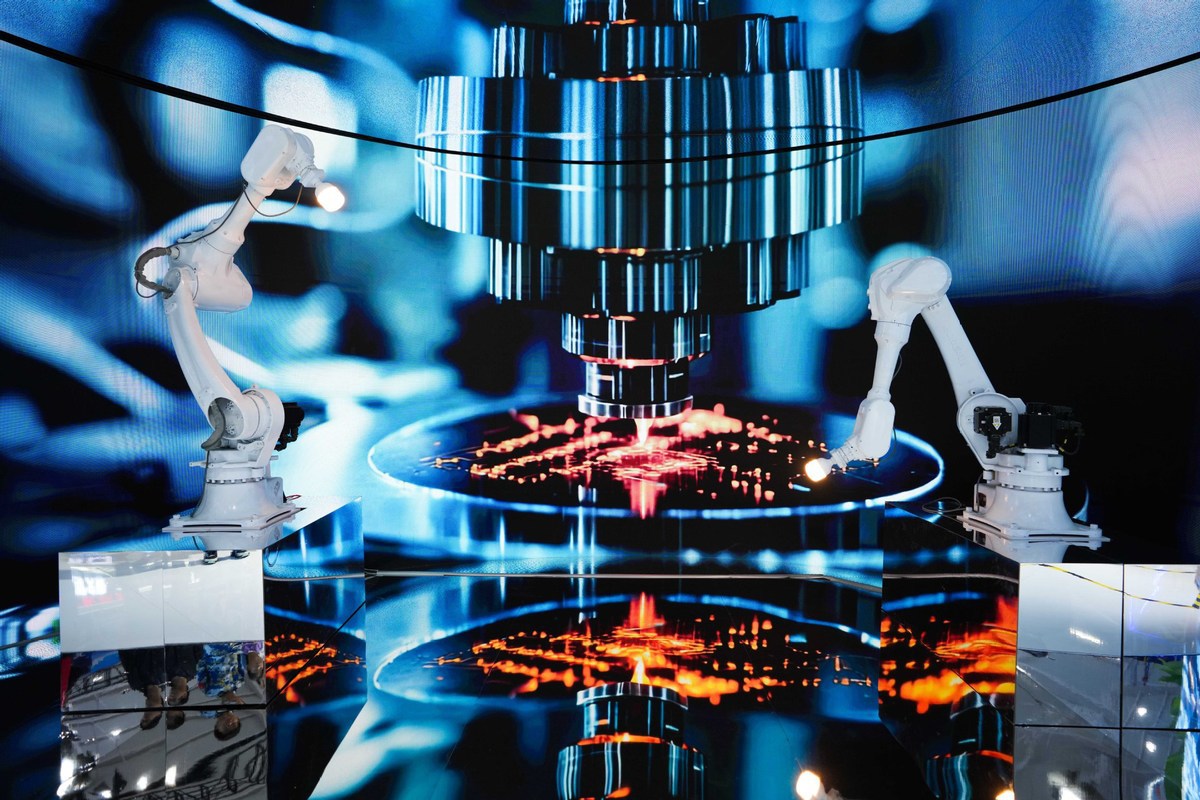

Recent years have seen the rapid application of electronics, digitalization and artificial intelligence in production technology. This development has opened up new possibilities to produce goods. But, at the same time, it is leading to a shift in the global skills landscape.

READ MORE: Firms urged to up AI, digital investments

Countries that were highly competitive in the past thanks to their expertise in traditional, mechanical engineering-based production technology are losing their dominance with the advent of new digital-based developments and therefore should realize the digital transformation. This is difficult for them because it requires major, long-term efforts to change long-established structures.

In contrast, countries whose people have a greater affinity toward digital technology and are more business-oriented will find it easier to realize and accept intelligent production technology. And intelligent production technology of the future should not be viewed as an isolated technology; instead, it should be seen as a part of the holistic global ecosystem.

Intelligent production technology will look as follows in the next decade: Many digital-based software tools will operate and control production. Thanks to digitalization, machines and other equipment in factories will be intelligent, and thanks to integrated sensors, they will control themselves and optimize their performance — they will also communicate with each other and coordinate their individual performance. As a result, they will strive for the optimum result.

Digital tools will be used at all levels of production to realistically simulate the processes in a factory as early as the preparation phase, ensuring the start of a successful new production process.

Sector-oriented, optimized and intelligent production structures are likely to emerge in the next decade. For example, production models are being developed for the aviation, automotive, medical and other industries.

Also, in the next decade, humanoid robots will take over all activities that do not require human sensory motor skills, becoming part of the production process. This development can be compared with the service robots in hotels found almost everywhere in China. In the past, humans performed room service in hotels. Today, it is done by service robots in many hotels.

Besides, logistics in and between factories will be handled by automated guided vehicles or service robots, and the machines and equipment in smart factories of the next decade will be modular units that can be combined technically and numerically as required.

In this way, production that can adapt to rapidly changing situations will be achieved.

Traditionally, production lines were built according to a flow principle. Such a production process is rigid and risky. If one link in the production chain fails, the entire production line comes to a halt. The new production model will be the so-called matrix production model, which will allow different products of a product cluster to be manufactured in a single factory. Hence, a factory in the future will comprise production islands with different work content.

Depending on the product specification, the materials will be routed to the designated production islands. In this way, production can be realized for different variants of a product.

Incidentally, matrix production is also less susceptible to faults, because if one station fails, the work can be shifted to another station. By reducing complexity, matrix production will become more resilient. For instance, in the event of a natural disaster or other emergencies, matrix production, along with the modular machines and equipment, will make it possible to increase the speed and capacity of new production.

Due to the application of AI, production will be controlled in the next decade in such a way that processes are optimized keeping environmental factors in mind, leading to a reduction in carbon dioxide emissions, energy costs and waste.

China has made unprecedented achievements since launching reform and opening-up in the late 1970s, with its development process becoming even more dynamic in recent years. China's digital talents and their ability to use new ideas quickly and profitably will also drive the development of intelligent manufacturing in the next decade.

ALSO READ: Are we losing the ability to think due to LLMs?

An increasing number of Chinese youths with forward-looking ideas are launching start-ups to turn their visions into reality, which will drive smart manufacturing in the future.

Chips are indispensable to intelligent production. In this regard, China may still be partly dependent on high-performance chips from other countries, but it will turn this disadvantage into an advantage through disruptive ideas, which will help it to develop advanced high-end industry-oriented chips.

Finally, the Chinese government makes ambitious, long-term, transparent plans for the country's development and sincerely implements them. Thus we can expect China to become a technologically advanced country in the next decade.

The author, a member of the German National Academy of Science and Engineering and the International Academy for Production Engineering, is an honorary professor at Nanjing University of Aeronautics and Astronautics.

The views don't necessarily reflect those of China Daily.