A plate of meatballs made with plant-based OmniPork is arranged for a photograph at a restaurant in Hong Kong on June 20, 2019. (PAUL YEUNG / BLOOMBERG)

A plate of meatballs made with plant-based OmniPork is arranged for a photograph at a restaurant in Hong Kong on June 20, 2019. (PAUL YEUNG / BLOOMBERG)

Slaughter-free meat is finally starting to make the jump from the lab to the factory line.

As Singapore becomes the first country to allow the sale of cultured meat, more startups around the world are preparing to test production of lab-grown meats like beef and chicken in factories. While there’s a long way to go, it’s a crucial step in getting cell-based products ready for supermarket shelves.

There are still lots of challenges to getting lab meat ready for supermarket shelves, such as cutting high costs, making large-scale production feasible and winning regulatory approval

Mosa Meat BV, started by cultured meat pioneer Mark Post, is among at least eight companies building or operating pilot sites. The Dutch company, which made the world’s first cultivated beef burger, has been raising funds for those efforts and plans to upgrade small-scale output in the first half of next year, before moving to a full industrial site as early as the end of 2022.

ALSO READ: Singapore approves sale of lab-grown meat in world first

“We proved already in 2013 that we can make a hamburger,” Mosa Chief Executive Officer Maarten Bosch said in an interview. “Now it’s all about scaling up and getting the cost where it should be. That’s exactly what this phase is all about.”

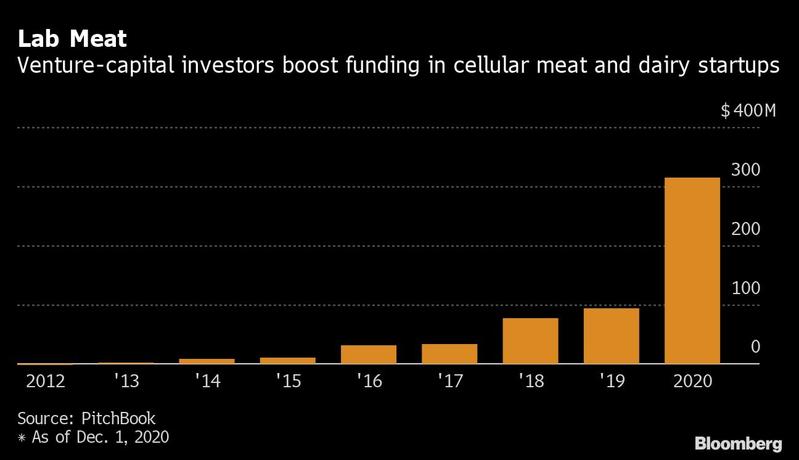

Lab-meat startups have grown from a handful in 2016 to at least 60 now, according to consultant Lux Research Inc. The sector wants to make production more humane and environmentally sustainable and has attracted record venture-capital funding this year. Just last week, Singapore approved Eat Just Inc to sell cultured chicken, at a time when interest in alternative proteins is growing.

There are still lots of challenges - from cutting high costs and making large-scale production feasible to winning regulatory approval. With cultivated meat costing US$400 to US$2,000 a kilogram to make, there’s still a long way until prices compete with conventional meats, according to Lux.

“Economies of scale are likely to help lower the cost in years to come,” said Harini Venkataraman, a Lux analyst in Amsterdam. “That is why these pilot plants are such important milestones.”

The cell-based meat market is projected to reach US$140 billion in the next decade, according to forecasts compiled by Blue Horizon Corp AG, which invests in alternative proteins.

READ MORE: Alternative meat can sustain food systems

Startups announcing test plants include Memphis Meats Inc, which has received backing from Richard Branson and Tyson Foods Inc, as well as cell-based seafood maker BlueNalu Inc. Companies such as BioTech Foods, SuperMeat and Eat Just already have started testing out sites.

“It’s not a question whether this is feasible,” said Ido Savir, CEO of SuperMeat, which has started a test kitchen for cultured chicken in Israel. “It’s a question of how long it will take us to go from a pilot setting, where we’re at, to a commercial scale. Things are becoming very exciting now.”